As the rate of many endothermic chemical reactions double with a 10 C increase in temperature, it is important to be able to elevate and control temperature within the key components of SI system. Therefore it would appear that the best way is to place the entire instrument, including reagent solutions, into an air incubator. While this is, indeed, a correct approach for the study of reaction kinetics and enzyme inhibition, (Yan Chen 2006, Lähdesmäki 2009) it is not the most efficient way how to optimized sensitivity of an assay.

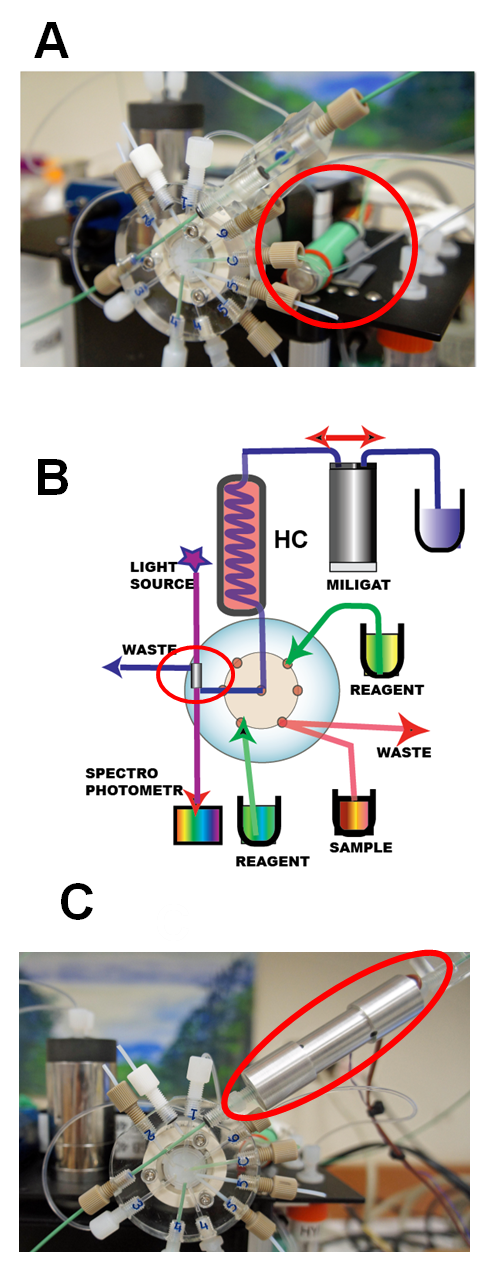

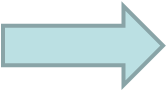

When using SHC protocol, based on incubation of sample with reagents in the holding coil, it is sufficient to control only the temperature of the holding coil (2m long 0.8mm I.D.), (A) . This is because the reactions have already proceeded as far as desirable in the coil and therefore the flow cell does not have to be thermostated (2.2.18.)

When using SFC protocol, based on incubation of sample with reagents in the flow cell, it is necessary to control the temperature within the flow cell, where the reaction rate is being monitored. If the flow cell is situated within the LOV module, and has a small internal volume (B) it is feasible to control its temperature by heated carrier stream, using careful flow programming.

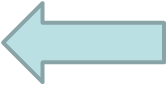

The external long light path flow cell has to be thermostated by a controlled heater (C). While it may seem to be useful to also preheat the reaction mixture in the holding coil, in order to avoid a lag phase (2.2.23.), this option should be carefully investigated, since it may cause a loss of sensitivity, if a significant amount of product would be formed, before the reaction mixture will reached the flow cell.

Yan Chen, A.D.Carroll, L. Scampavia, J, Ruzicka: Anal. Sci. 2006, 22, 9.

Thermostating SI-LOV System

2.3.17.